... ...

|

... ...

|

Display allHide all Display allHide all |

|

|

|

| | Manufacturing |

Power consumption reduced |

|

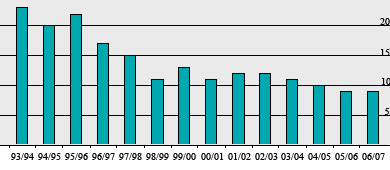

| Nominal Energy consumption in kWh to produce a unit in the production plant at Augsburg, Germany from 1993 - 2007 |

Fujitsu Siemens Computers’ production facilities in Augsburg, Germany, have achieved substantial savings in power and materials through an energy and environmental management initiative. The ISO-14001-certified site serves as benchmarks to the rest of the industry and underscore the company’s commitment to the environment.

The processes employed at Augsburg are the result of a global strategy to manufacture all Fujitsu Siemens Computers products in a sustainable way. The company, which invests substantially in energy savings measures at these facilities each year, makes the most of raw materials, energy and water during production by incorporating recycling loops into the assembly lines. In addition, every supplier and production partner must meet environmental compliance criteria set out in Guideline FSC03230. By publishing our manuals electronically, we have reduced the amount of printed paper that we use by 70%. This equates to a saving of more than 500 tons of paper per year!

Numerous measures introduced since the early-1990’s have cut the electricity required to manufacture a PC at Augsburg in half, and power consumption at the plant has declined by 60 percent in the same timeframe even as production has risen. In 2007 alone, Fujitsu Siemens Computers expects to reduce energy costs at Augsburg by €500,000 resulting in a total reduction of C02 emissions to date by 3,300 tons through its environmental management initiative.

CO2 emission reduced

Each factory has its specific environment and conditions.

In our main production site in Augsburg more than 2,000 employees are active in the manufacturing of business PCs, business mobiles and industrial standard servers, but also in administrational, operational and engineering tasks. The location is optimized to the specific requirements of these various functions. From 1993 to 2007, we cut the CO2 emission per unit in our production in Augsburg by about 60 %. This has been achieved by constantly improving manufacturing processes.

How does the company achieve this saving? Through innovative production measures such as heat recovery techniques, energy-saving lighting and motion detectors, concrete core cooling, well-regulated air compressors and air conditioning systems with circulating heat exchangers and advanced building control systems. Fujitsu Siemens Computers even operates an innovative ‘free cooling’ system through which water is cooled naturally when outside temperatures dip below seven degrees Celsius.

Fujitsu Siemens Computers is continuously looking to further reduce CO2 emissions – through improvements in sourcing, processes and facility management.

This is a logical consequence of our comprehensive green approach to caring for the whole product lifecycle.

Our main goal is to reduce the energy consumption of our products during their use phase as those improvements have a much higher impact on the overall energy balance than manufacturing, logistics or recycling.

Amount of renewable energy used

At least 15 % of our purchased electricity in 2007 was generated by renewable energy sources. In order to reach the European sustainability target of 20 % in 2020 we are carefully investigating alternative energy sources to further reduce our greenhouse gas emissions. One of our efforts is directed at using renewable energy sources in order to run all our sites using green power.

Fujitsu Siemens Computers’ production facility, based in Augsburg, Germany, has achieved substantial savings in recent years in power and materials through an energy and environmental management initiative. Both ISO-14001-certified sites serve as benchmarks for the rest of the industry and underscore the company’s commitment to the environment.

The processes employed at Augsburg are the result of a global strategy to manufacture all Fujitsu Siemens Computers products in a sustainable way. The company, which invests substantially in energy savings measures at these facilities each year, makes the most of raw materials, energy and water during production by incorporating recycling loops into the assembly lines. In addition, every supplier and production partner must meet environmental compliance criteria set out in Guideline FSC03230. By publishing our manuals electronically, we have reduced the amount of printed paper that we used by 70 %. This equates to a saving of more than 500 tons of paper per year! |

|

| |

| |

| |

| |

| |

| |

| |

| |

|  |  |  |

|

|

Information |

|

|

|

|

Energy Efficiency |

|

|

|

|

Energy Saving Tips |

|

|

|

|

News |

|

|

|

|

Organizations |

|

|

|

|

Related products |

|

|

|

|

PDF requires

Adobe Reader | |

|

|